Rotating Components - Newington, CT

Complex Rotating Components for Aerospace Engine Applications

Differentiated from competitors through engineering depth, proven capabilities, customer relationships, focused product portfolio and optimally-configured modern facilities.

- World Class concurrent engineering and new product development embedded within value streams

- OEM recognized “Best in Class” manufacturer of Bladed Rotors/Disks for commercial and military engine applications. In 2021, HAU’s Newington facility was officially awarded

Raytheon Technologies’ Supplier Gold recognition.

- Integrated Manufacturing Cells providing lights out/closed loop machining capability

- Significant investment 2012-2017 provides best-in-class machining and special process capacity to support business growth

- Engine component processing capability up to 60” in diameter

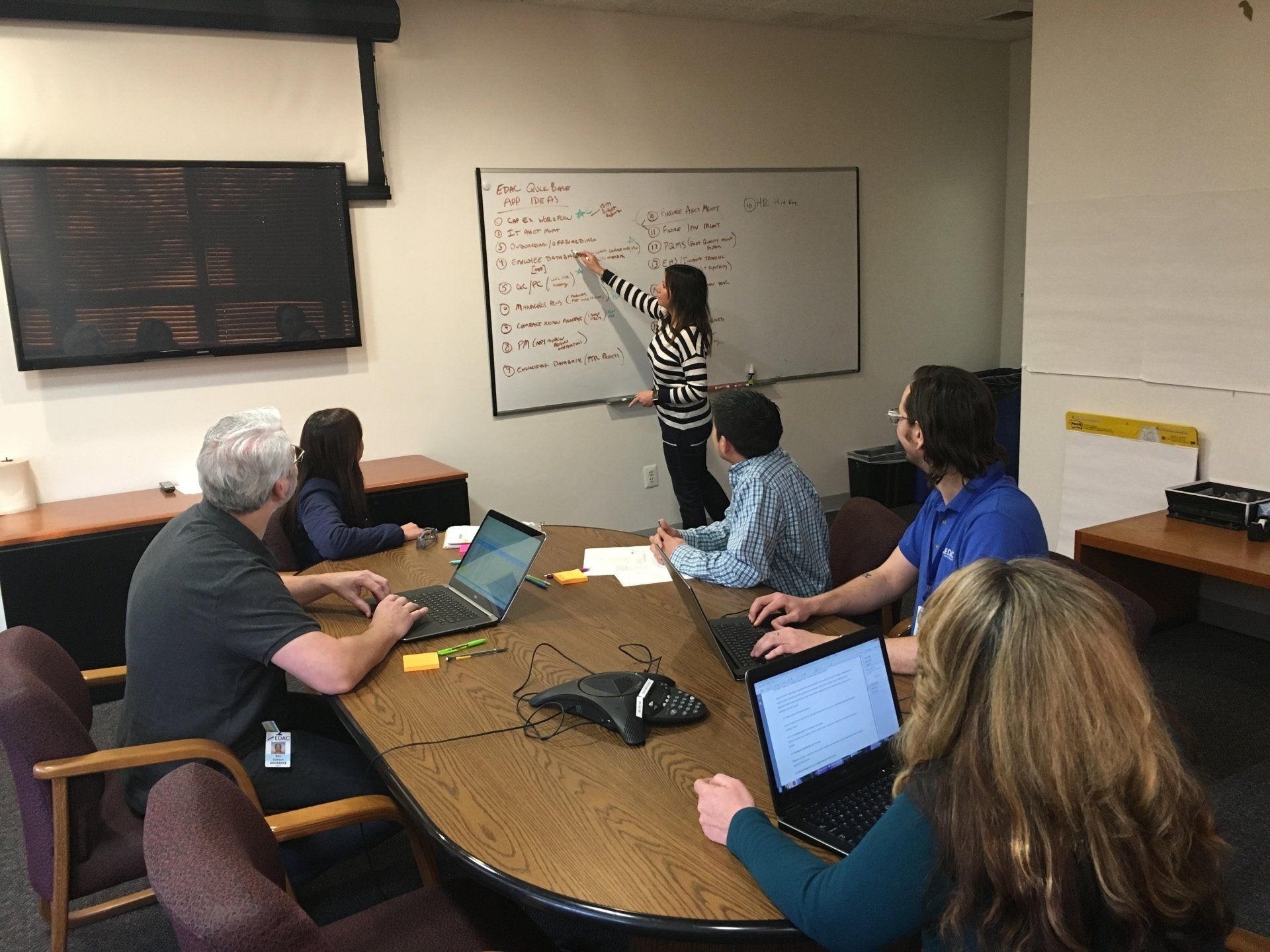

Rotating Components' Growth is Supported by Continuous Improvement:

Lean initiatives are established by Rotating Components’ Leadership Team, driven by a dedicated onsite Lean Leader and supported by our Functional Executives. Monthly Rapid Improvement Events are organized to support core business objectives with a focus on quality.

CONTACT US

Rapid Improvement Events are structured to improve internal manufacturing operations, internal administrative/system processes and critical vendor performance to ensure predictable manufacturing outcomes. The Rotating Components team embarked on its Lean journey in 2016 and make daily progress organizing data, identifying waste, and using problem-solving techniques to drive systemic transformation.